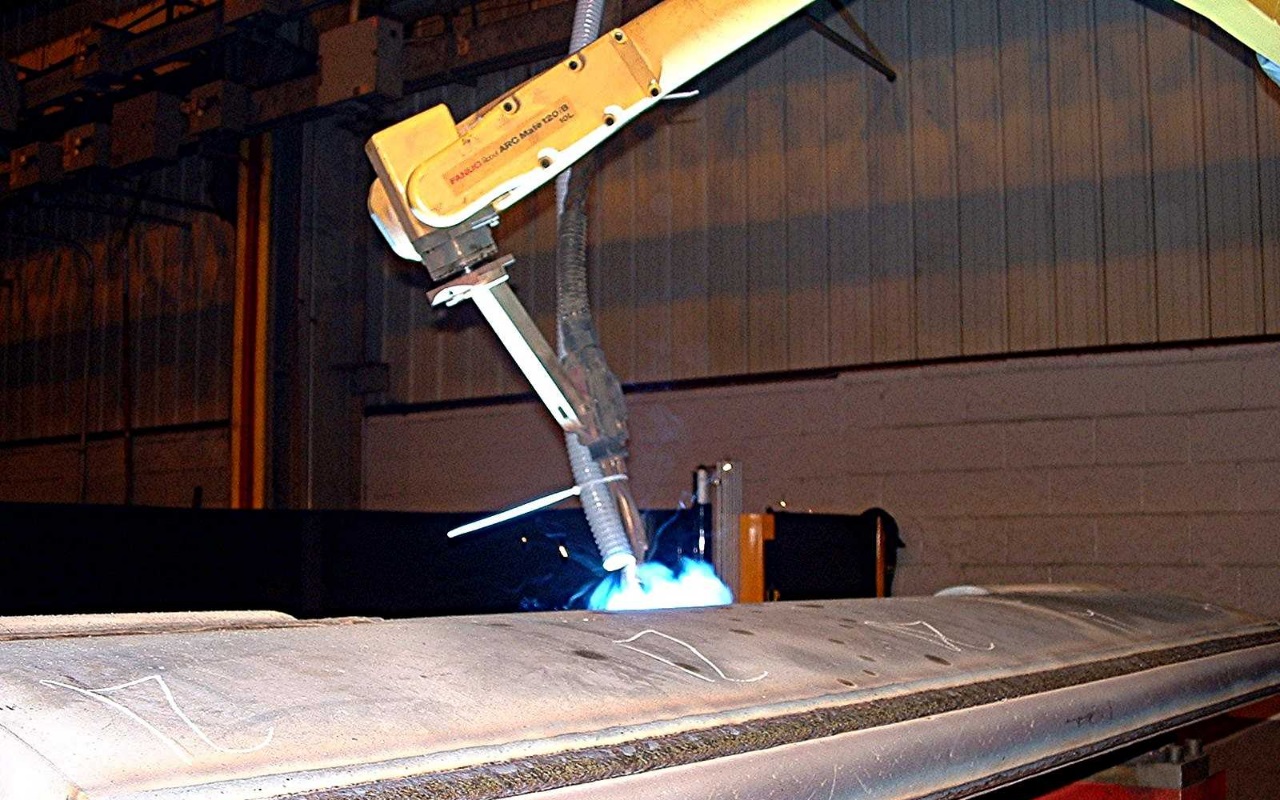

Robotic and automated welding continue to gain popularity as manufacturers look for higher productivity, consistent quality, and reduced labour challenges. But automation doesn’t eliminate one of the biggest issues in any welding environment: welding fumes.

To protect workers, meet regulatory requirements, and extend equipment life, welding robots must be paired with efficient fume extraction solutions. Fortunately, there are several ways to do this—each suited to different budgets, production layouts, and robot configurations.

Below are four proven approaches, ranked from the least expensive and simplest to the most comprehensive and costly.

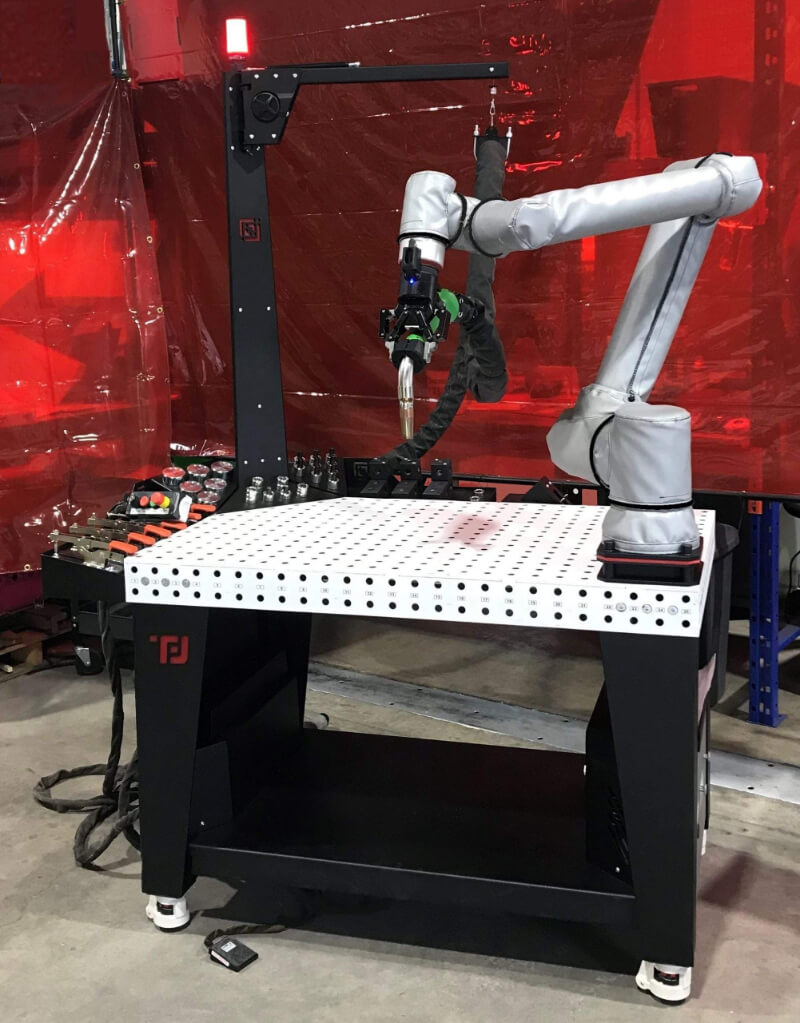

Fume Extraction MIG Gun on a Robot or Cobot

One of the most cost-effective and efficient solutions is to mount a welding fume extraction gun directly on the robot or cobot.

Because the suction is integrated at the torch, this method captures the fumes at the exact point of generation, requiring minimal airflow compared to other systems. That means smaller equipment, lower energy costs, and easier installation.

We’ve worked with multiple cobot integrators who simply paired a high-performance portable extraction unit with a fume-extraction MIG gun—and the results were excellent. Because there is no external nozzle or arm, the robot movement remains unobstructed and there is zero risk of interference with the work envelope.

Nozzle or Flexible Hose Adapted to the Robot

If a fume extraction gun cannot be used or you want to add source extraction to an existing robot, another effective method is to add a custom nozzle or flexible hose near the weld point.

This solution offers similar airflow efficiency to the extraction gun because the capture happens close to the source. However, it requires careful engineering:

- You must find a reliable way to mount the nozzle or hose.

- The position must stay optimal during the entire weld cycle.

- Robotic movement introduces a real risk of interference, so spacing, angles, and trajectory programming are critical.

It works very well when properly integrated, but it demands more design time than option 1.

Fume Extraction Arm

This option only works if the robot welds in a very small, predictable space—for example, an automated welding setup where a pipe or tube rotates (commonly referred to as a welding lathe or rotary welding fixture), while the torch stays stationary.

Because the weld point does not move around the cell, a fixed extraction arm can be positioned to act like a compact hood.

This offers good fume control with much lower airflow requirements than a full hood enclosure.

It is also significantly cheaper to install and operate compared to a large extraction hood.

Enclosed Extraction Hood for the Robot

The most comprehensive—and most expensive—solution is to place the robot inside a ventilated enclosure or under an extraction hood.

This method captures fumes through general extraction rather than source capture. It can be very effective, but the trade-offs are significant:

- Requires much higher airflow compared to the other options.

- Higher buying and operating costs.

- The enclosure can slow down loading and unloading, unless the doors or access systems are automated.

- Installation cost is the highest due to structural requirements and larger equipment.

Still, when source capture is not feasible, a hood provides reliable, predictable fume control.

A Note on Duty Cycle and Equipment Durability for Robotic Welding

Unlike manual welding, robotic welding typically operates at a much higher duty cycle, meaning the robot welds far more consistently and for longer periods of time. This places significantly greater demands on the fume extraction equipment. To maintain consistent performance and avoid costly downtime, both the extraction tools and the vacuum units must be highly durable and capable of delivering stable airflow hour after hour.

Small or inexpensive extraction units are not designed for this type of continuous operation. They often struggle to provide adequate vacuum, suffer accelerated wear, and experience rapid filter clogging—reducing capture efficiency and increasing maintenance requirements. Over time, this results in inconsistent fume control and more frequent interruptions in production.

This is why our systems are engineered specifically with robotic duty cycles, durability, and long-term performance in mind, ensuring stable airflow, longer filter life (when necessary), and maximum uptime for automated welding cells.

Conclusion

There is no one-size-fits-all solution for robotic welding fume extraction. The right approach depends on the robot type, welding process, spatial constraints, and budget.

To summarize the hierarchy:

- Fume extraction MIG gun — lowest cost, highest efficiency, zero interference

- Nozzle or hose at the torch — very efficient but requires careful integration

- Extraction arm — only for very small, fixed welding areas

- Enclosed hood — most robust but highest cost and airflow demand

With the right setup, robotic welding cells can achieve outstanding fume control while maintaining productivity.

3 Ways to Take a First Step Towards a Fume-Free Environment

1 – Attend Our Webinar

2 – Request our Compact Guide “30 Expert Tips for Eliminating Fume”

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

3 – Contact Us

Free demos everywhere in Canada and the US.

1-800-922-2522

info@henlex.com

Or use our chat system at the bottom right corner.